f4b in the Supply Chain

The technology behind f4b

has been used to provide analytics and warehousing for managing

supply chains since the early noughties.

The recent addition of f4haulage compliments this suite of software

providing entry level management of haulage activities.

We believe that informed decisions and keeping customers informed are

key to managing any business so our supply chain software comes with

powerful, flexible and easy to use analytic capabilities built in.

Reporting on customer stock, movements and Key Performance Indicators

(KPIs) is a breeze.

Using the f4b components MultiStock

and MultiStat

as part of a MultiFreight

solution provides for a comprehensive solution to supply chain

management that deals with multimodal transport, customs

documentation, Electronic Data Interchange (EDI)…

The current f4b user interface is based on Microsoft .NET technology and

provides the familiar feel of a spreadsheet while being a true secure

client server SQL interface. This means that users require less

training, the interface is fast while server loading is low and the

back end database can be SQLServer, MYSQL, PROGRESS…

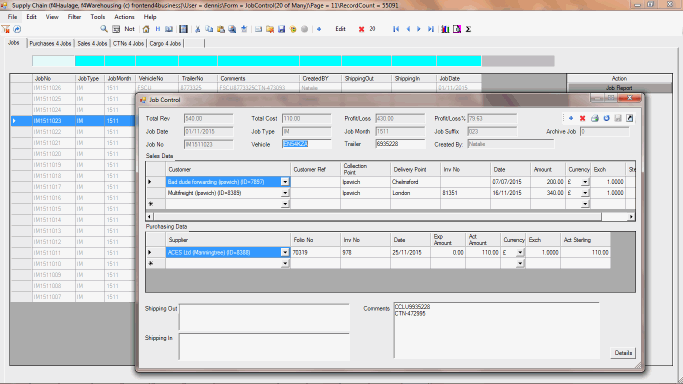

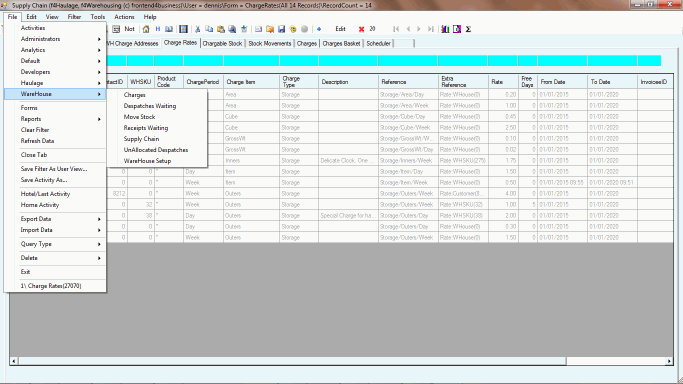

Click image to enlarge/reduce

Fig 1. How f4b and Multifreight manage your supply chain

f4haulage

This

entry level haulage application provides screens for entry of multi

pick up and delivery haulage jobs along with costs, income and

associated cargo details. The route planning capabilities of f4b can

be used to establish the mileage associated with additional way

points.

f4haulage links seamlessly with f4warehousing.

Fig 2. Haulage jobs, sales (collection and delivery points), costs of subcontracted haulier

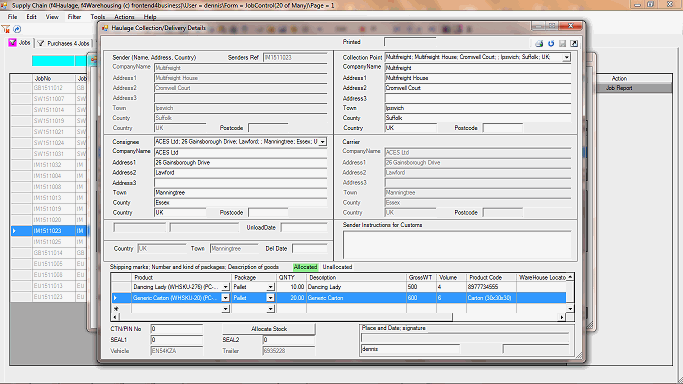

Fig 3. A haulage job with cargo details. Note this job is actually a despatch from a warehouse and the option to Allocate Free Stock from the warehouse is provided.

f4warehousing/MultiStock

This

product works in conjunction with both f4haulage and Multifreight.

Receiving

cargo.

Setting

a haulage job's Consignee to an address designated as a warehouse,

results in the cargo being added to Expected Receipts of the Supply

Chain views. Here they can be received into the warehouse by adding

them to the Receipt Basket. Auto and manual put-away facilities are

then provided.

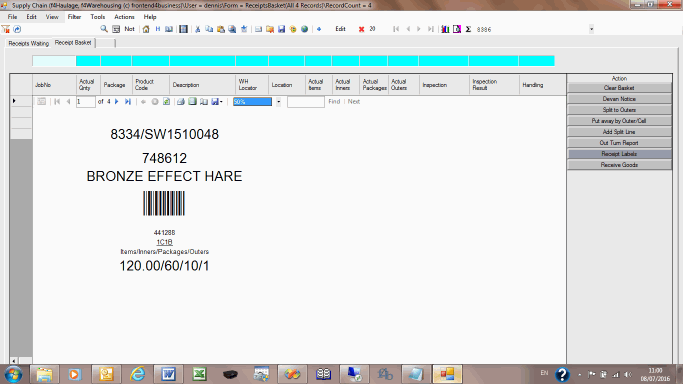

Fig 4. Using the Receipt Basket to receive cargo into a warehouse

Fig 5. Barcode Labelling of Receipts

Despatching

Cargo

Setting

a haulage job's Collection Point to an address designated as a

warehouse, results in the cargo being added to the Supply Chain views

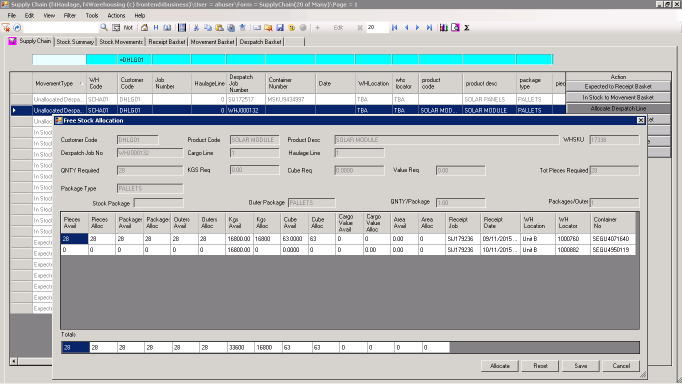

initially as Unallocated Despatches. Using f4haulage, free stock can be allocated as the cargo is added using the button 'Allocate Stock' (see Fig 3) or later when stock becomes available (see Fig 6).

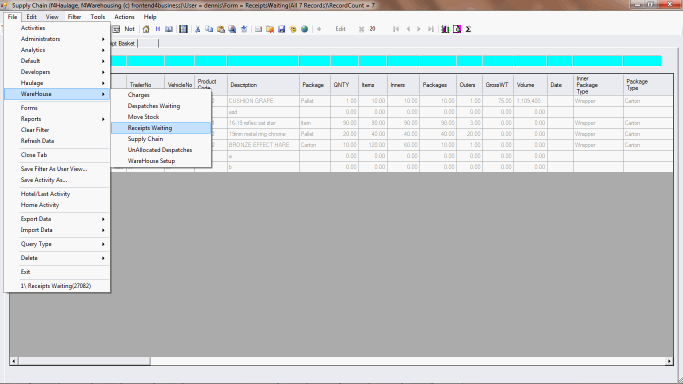

The

Supply Chain shows Expected Receipt, In Stock, Unallocated Despatch

and Allocated Despatch lines as a single view/grid. A running total

of this view makes potential stock-outs obvious. You can filter the

grid or use the favourites at the bottom of the file menu to find the

Unallocated Despatch lines you are interested in allocating as cargo.

Allocation

can be First In First Out (FIFO), least picking distance, least

number of picks...

Fig 6. Allocating warehouse stock to a despatch haulage job

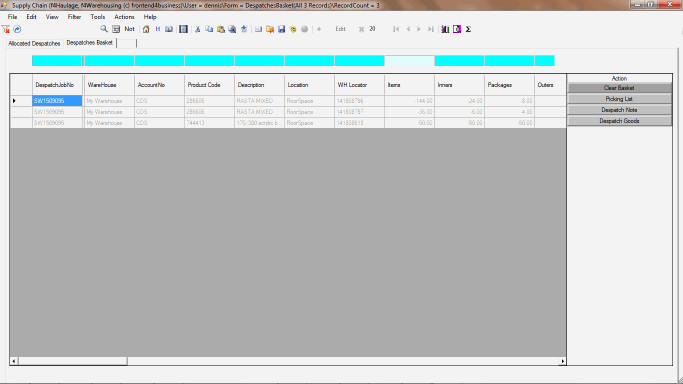

Fig 7. Allocated despatches are added to the despatch basket where picking list can be produced

Moving and Consolidating Warehouse Stock

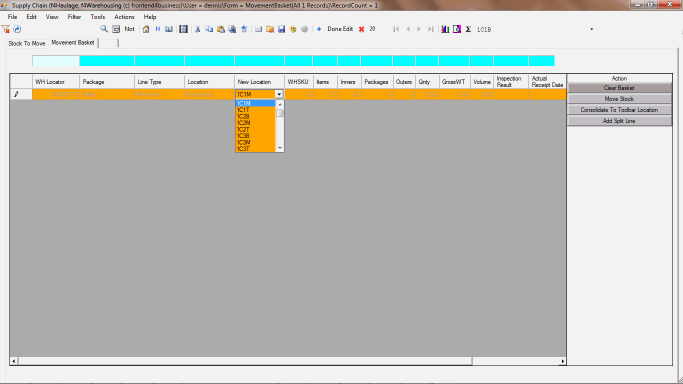

Fig 8. Using the movement basket

Charging for Warehousing

f4warehousing/MultiStock

keeps a record of all stock movements into, around and out of your

warehouses. From these movements customer stock levels can be seen

and reported.

Charges

can be set up by warehouse, package style (eg pallets) quantity, item

quantity, weight, volume etc.

A

scheduled task is set up to automatically interrogate customer stock

levels, calculate customer charges and post them to your accounts

package.

Fig 9. Setting up and running warehouse charges

|